As is the normal process for treating cast components, Moddex connectors are hot dip galvanized before our critical locking screw thread is machined (threads do not survive the intense heat and activity in the zinc bath, including unacceptable build-up of zinc in threads).

Our differentiation is in the thread protection coating that we apply after the hot dip galvanizing and thread cutting process.

This final zinc coat covers both the previously hot dip galvanized surface and the freshly cut threads. This creates a dual finish on the main body of the connector and a durable coating on the raw steel that is exposed during the thread machining process.

The long term effects of this additional coating are very apparent in the field, with the threads holding up exceptionally well even in corrosive environments and supported by our product warranties.

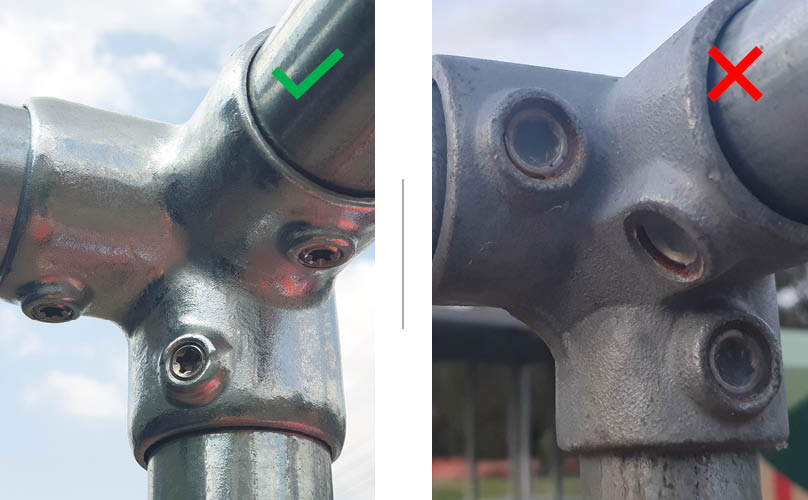

It doesn’t take long to notice failure in pipe connections that don’t apply a thread protection coating!

This comparison image shows failure of a thread that is not protected, beside a superior Moddex connection with thread treatment. Also demonstrated are the smooth edges of our Ergonomic Connector Designs.

From this section

- Adjustable Top Rail Fitting

- Cyclist Footrests

- DEXX® Locking Screw

- Ergonomic Connector

- In-Line Joiner

- Innovation Spotlight: G390™ by Moddex – A Game-Changer for Corrosion Protection

- Modular System Connectivity

- Smooth mandrel bends compared to bulky elbow fittings

- The Tuffgard® Toeboard

- Three Material Types

- Weld-Free Kerbrail