With non-residential and infrastructure construction in New Zealand forecast to increase over the next two years, this signals busy times ahead for architects, engineers and project managers.

Time is a valuable and irreplaceable asset.

At Moddex NZ, we talk about the power of a day. Every day you lose on a project comes at a cost – financial cost, opportunity cost and a potential cost to your reputation too. Thanks to our modular innovation, we’re at least 50% faster on-site than any other barrier system, with a fast lead time from customisation to delivery. What might take other suppliers and installers two weeks to deliver, we can turn around in a couple of days.

Protecting the public and seals in Kaikoura

The Iron Gate Bridge in Kaikoura is a dynamic environment where the main highway has the sea on one side and cliffs on the other. Decommissioning of the civil works resulted in a public hazard and an urgent requirement for handrail. In addition, barrier systems were needed to prevent the local seal population from leaving the waters’ edge and creating a hazard on the highway. Moddex was selected by North Canterbury Transport Infrastructure Recovery to supply and install a handrail to remove these risks to the public and sea-life. The modular, pre-configured Tuffrail and Connectabal systems were delivered to site flat packed and the only tool needed for installation was a battery-operated hand drill. With no need for equipment, machinery and welding, the installation was 30% faster than any previous barrier system.

To help you streamline project workflows and timelines, we’ve invested our engineering and technology expertise to bring you Moddex modular balustrade and handrail kits that enable installation in a fraction of the time. By investing in Moddex, you’re also investing in the highest-quality solution with the lowest ongoing maintenance costs and an unrivalled low lifetime cost of ownership.

Unlike other modular systems on the market, Moddex modular kits come complete with custom-designed modular connecting components. Being modular, they’re adjustable, removing the potential of costly and time-consuming on and off-site customisation at installation stage. If obstacles occur at the installation, our innovative components like the in-line joiner, offer an easy fix and are quick and easy to install. Moddex modular solutions are 100% no-weld, eliminating any on- or off-site cutting, power supply issues, obstructive welding tools or time-delaying site shutdowns.

Eliminating welding and cutting hazards at Mahora School

Mahora School in Hastings caters for students from Years 1 to 6. A major upgrade of facilities included handrails to improve accessibility and safety for students. With tight project timeframes, Moddex Connectabal and Assistrail products were sent to the site pre-configured and ready for immediate installation. Being fully modular, no welding or cutting was needed which eliminated hot works permits, toxic fumes and safety hazards for installers, teachers and students.

Your Moddex kit is delivered complete with all components and an easy-to-follow installation guide. Every component is numbered and corresponds to the guide, avoiding confusion, time delays and giving fully-compliant results. You can install yourself or use one of our highly-experienced Moddex installation teams.

3.4km of rail at the Mangere Waste Water Treatment Plant

A Biological Nutrient Removal (BNR) facility constructed as part of a $136 million upgrade of the Mangere Waste Water Treatment Plant required almost 3.4km of top rail, mid rail and kick rail to provide safe access over the crisscrossed concrete water tanks of the clarifiers and BNR system. The no-weld Moddex Tuffrail system was pre-engineered and pre-configured, and arrived kitset to site for easy installation by McConnell Dowell and HEB construction teams.

Our Moddex way is to work closely with you from the get-go to ensure everyone is on the same page. We build clarity and precision around the system you need, ensuring the ideal end-to-end solution is delivered to you as-specified. Measuring and scoping out your project, we then create a design-intent drawing to identify and engineer solutions to any potential problems in advance, saving time onsite later on.

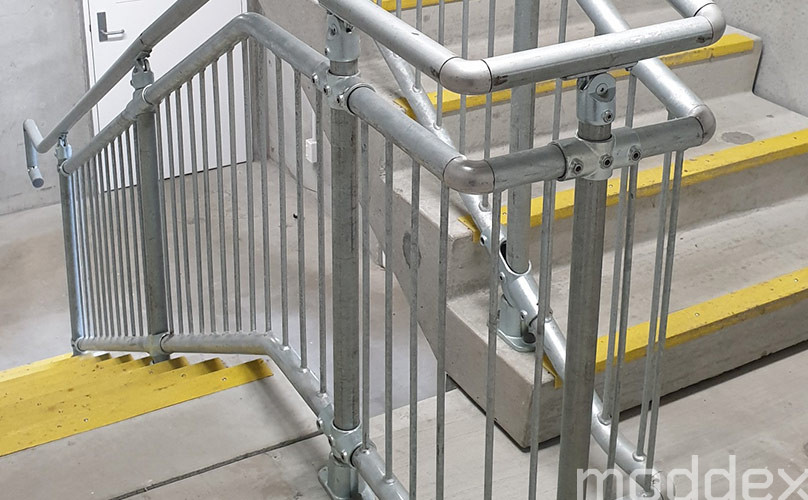

Internal stairs at Tauranga Crossing

Tauranga Crossing is the Bay of Plenty’s newest regional shopping centre and Moddex were selected to provide handrail and balustrades for the internal egress stairs. The project included site measures, CAD design, compliance documentation, producer statements, freight to site and install. The key benefits of the Moddex Tuffrail system for the client included delivery of pre-configured product to site, speed on site with no on-site requirement for welding or cutting, and installation completed within 10 working days.

Once approved, we deliver your Moddex system quickly, efficiently and on time, every time. That’s our guarantee to you.

Our knowledgeable teams are available to give you advice, taking the worry out of your handrail and balustrade solution to enable you to focus your time and energy on other opportunities. Visit moddex.com today to find out how Moddex modular kits can help fast-track your project delivery.

At Moddex, everything fits™.