Funded through the Government’s Crown Infrastructure Partners Shovel-Ready Fund and recent budgets, KiwiRail has strengthened its South Island operations with a new rail mechanical hub at Waltham Yard, Christchurch. This purpose-built hub is now the primary maintenance facility for locomotives, passenger carriages, and wagons in the region.

The facility, which opened this year, supports KiwiRail’s growing fleet, including 47 new low-emission locomotives joining the South Island this year. Spanning 9,400 square meters, the building houses 25 maintenance berths, an underfloor wheel lathe, a wheelset drop table, and advanced locomotive axle weigh systems.

Award-Winning Sustainability Initiatives

Sustainability was a core value throughout the project. The use of recycled materials is what won this project the HEB Circular Economy (Reduce/Reuse/Recycle) of Construction Materials award in 2023 and finalist in the WasteMINZ Conference, Expo + Workshop Awards for Excellence in the contaminated land management category.

Where possible, sending waste material to landfill was avoided by re-using and recycling construction materials. Examples of this were:

- After demolition, concrete and steel were separated on-site, with the steel sent to a local scrap merchant for recycling, while the concrete was crushed and repurposed as construction aggregates.

- A total of 6,000 tonnes of asphalt was sent to a construction company for recycling and reuse.

- Additionally, all 5km of rail track in the yard were second-hand, repurposed from other parts of KiwiRail’s network.

Solutions were sought for various parts of the project that minimised environmental impact during construction while helping beat the looming project completion deadline – and Moddex’s modular barriers, designed and manufactured offsite, were the perfect alternative to traditional onsite welded barriers that would have typically taken much longer to fabricate and install.

Benefits of Moddex products for the KiwiRail Waltham Centre

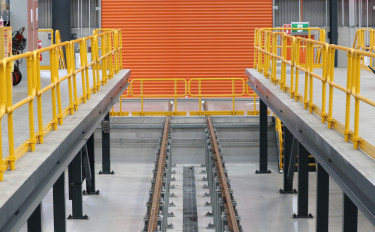

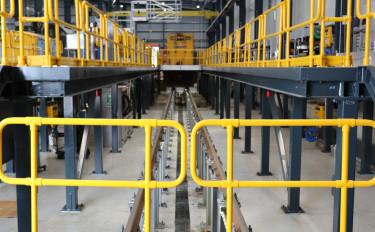

Moddex worked closely with the main contractor, Calder Stewart on this project. The project featured multiple train service roads and pit lanes, requiring over 1km of our Tuffrail Industrial Handrails, including both fixed and removable options. Moddex was chosen due to the suitability of our proprietary Tuffrail barrier range, which aligned perfectly with the project’s sustainability specifications.

Additionally, Moddex were able to integrate our Tekla design software with the full building model to meet all barrier and handrail requirements.

One of the key challenges faced was the design and precast setup for the removable barriers on the pit lane platforms. Moddex addressed this by providing precast set-out jigs, enabling the installation of cast-in sockets to be coordinated with other trades.

Thanks to the advanced modelling capabilities, Moddex was able to manufacture large sections of the project scope even before the site’s final as-built details were available.