Accessibility with Flexalyte Kerbrail

Designed to meet the requirements of AS1428, the Moddex Flexalyte Kerbrail system provides a weld-free solution for ramp accessibility and safety.

The kerbrail system, integral to the Assistrail Disability Handrail and Conectabal Commercial Balustrade ranges, offers a compliant solution for ramps and their landings. It is particularly relevant for ramps intended for public use or in situations where regulations require its use.

The Flexalyte Kerbrail stands out for design and alignment with the handrail, the extrusion is nice and straight, like the handrail, providing a more appealing line than traditional flat bar solutions which typically create warp. Its easy and quick installation process makes it a practical choice for various applications. The Flexalyte Kerbrail is not just a functional element but also an aesthetic enhancement, blending seamlessly with the existing Moddex systems.

Seamless transitions and joins

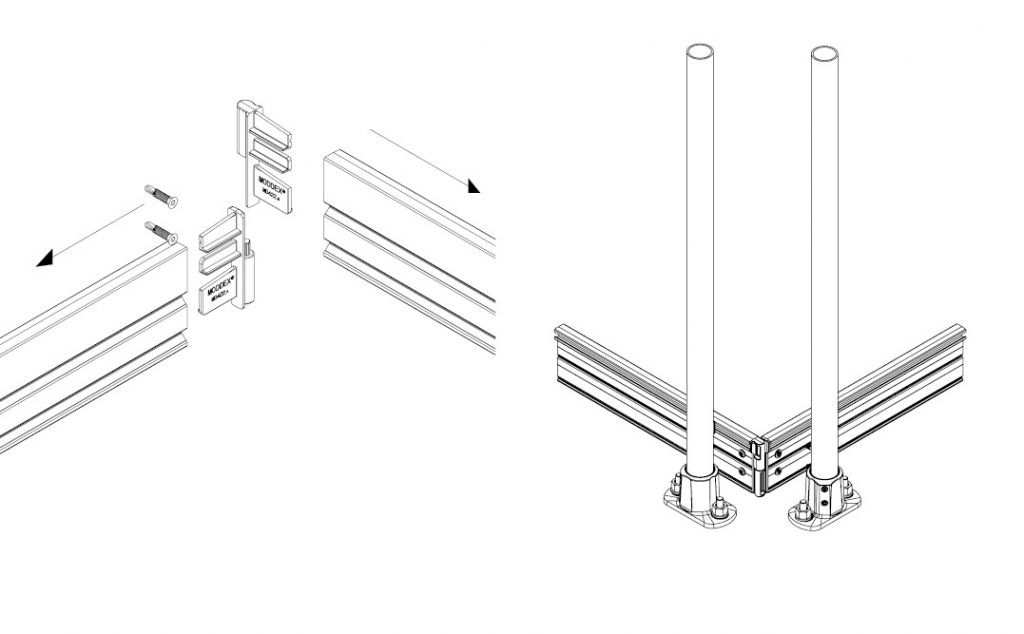

How does a level 90-degree corner work with Flexalyte Kerbrail?

Simple! There are two hinge components that are placed into the extrusion, screw off with self-drilling screws and screw off extrusion to the handrail stanchion.

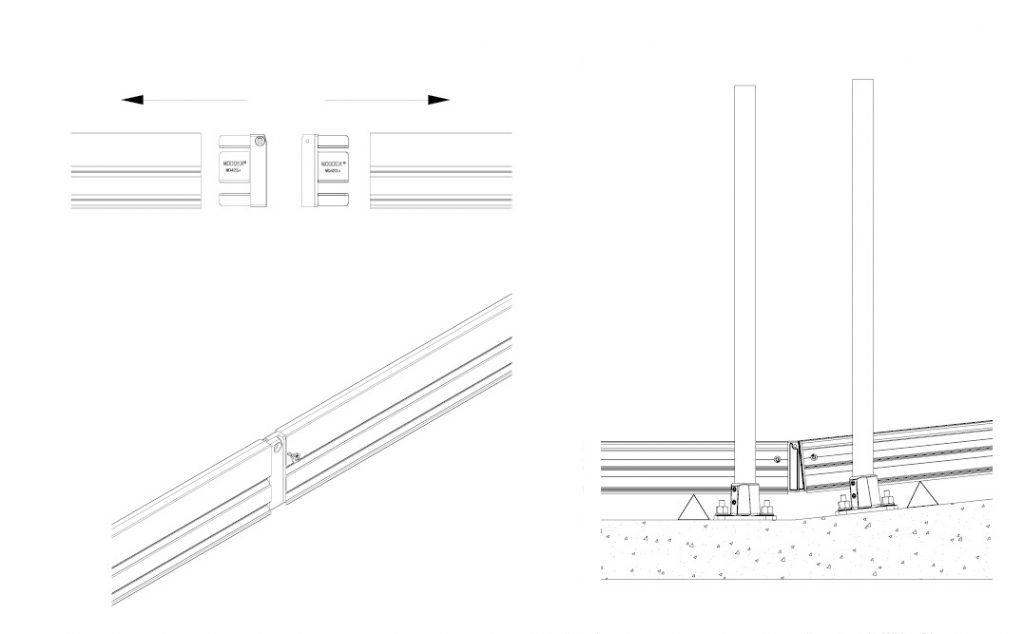

How does Flexalyte Kerbrail transition to the angle of the ramp?

Achievable using the transition joiner components – this works like the hinge components and the angle is set to the desired location.

Key compliance guidelines for kerbrails under AS1428 include:

- Kerbrails are needed on both sides of a ramp unless there are solid walls on one or both sides.

- The top of the kerbrail must not be within 75mm to 150mm above the finished floor level.

- The maximum gap between the bottom of the kerbrail and the finished floor is 75mm.

- The ramp-side face of the kerbrail must be flush with or no more than 100mm behind the ramp-side face of the handrail.

For more detailed information, please refer to Moddex’s guide on Achieving Compliance in AS1428 Applications.

From this section

- Adjustable Top Rail Fitting

- Cyclist Footrests

- DEXX® Locking Screw

- Ergonomic Connector

- In-Line Joiner

- Innovation Spotlight: G390™ by Moddex – A Game-Changer for Corrosion Protection

- Modular System Connectivity

- Smooth mandrel bends compared to bulky elbow fittings

- The Tuffgard® Toeboard

- Thread Protection Coating

- Three Material Types