The Big Changeover at Skyline Queenstown

Skyline Queenstown, a tourist attraction that’s served visitors in Queenstown for more than 50 years, has just undergone a significant transformation to improve visitor experience.

The second major upgrade since the cableway was built in 1967, the $250million project included the construction of a brand-new gondola system, including the top gondola terminal building, a new base terminal machine hall, a back-of-house area and a five-level carparking building.

Skyline Queenstown’s General Manager Wayne Rose, stated, “This will set the business up for the next 30 to 40 years.”

The five-level car parking building was constructed to accommodate the growing number of guests. With close to 400 new parking spaces, this multi-storey facility has created easy access to all Skyline Queenstown attractions, making it more convenient for both visitors and staff. No more searching for a spot – a smoother parking experience for everyone!

Moddex Overcoming Challenges in a Complex Project

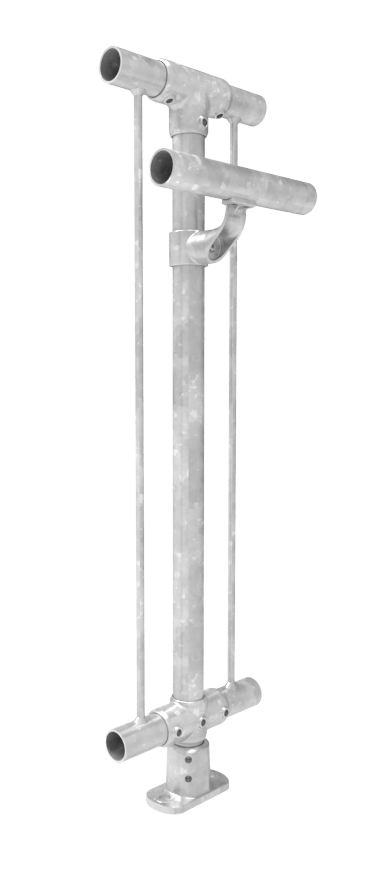

Working in collaboration with Naylor Love, Moddex was selected to supply our Connectabal Commercial Balustrades for the five-level car parking building. There were three egress areas included in the project that required NZBC (New Zealand Building Code) F4 & D1 compliant balustrade solutions.

During the project, Moddex faced complex challenges, including the need to meet the building’s unique seismic requirements. We had to design the balustrade in a way that could integrate seismic sliding joints to ensure safety standards and New Zealand Building Code compliance was met.

The project site also posed significant space constraints, and the installation program was relatively drawn out. Moddex’s prefabricated balustrades were the perfect alternative to traditional onsite welding methods that would have typically taken up a lot of space and taken much longer to fabricate and install.

Not only are Moddex’s balustrades manufactured offsite which cut out the need for onsite welding, but the flat-packed nature of Moddex’s modular system meant we were able to send product to site and store using minimal space. We could then install in progressive stages as areas became available from other trades. Read more about how Moddex’s handrail and balustrade kits cut installation timelines by 50%.

Additionally, Moddex’s ability to integrate seamlessly with the IFC building models to design, approve, and manufacture the balustrades ahead of site readiness, meant we could commence install as various project stages became available.