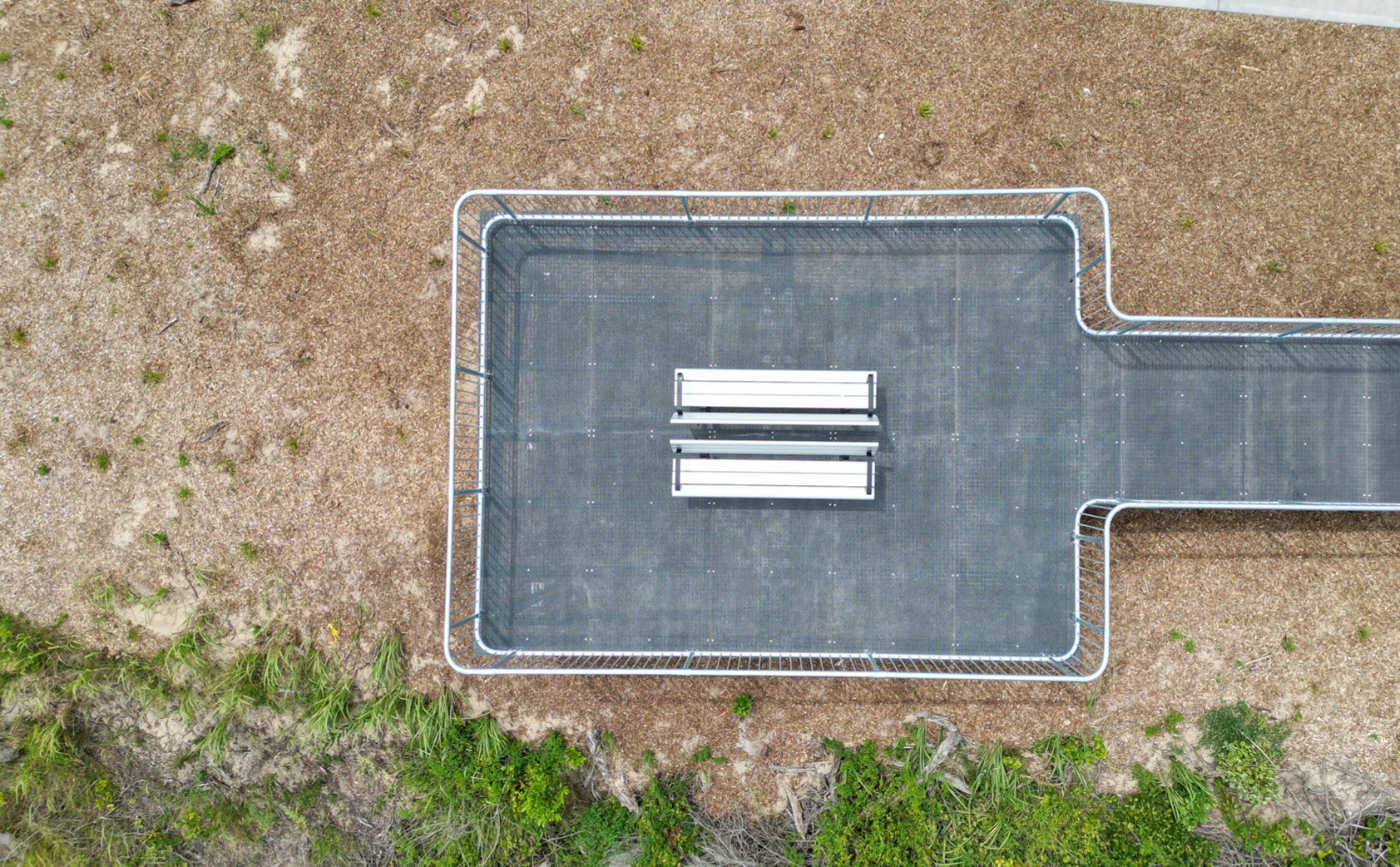

Customised modular railings: A perfect fit for a coastal pathway

Winding through Wyrrabalong National Park on the Central Coast, the Magenta Shared Pathway is part of a continuous cycling and walking network that will eventually connect Victoria to Queensland. To ensure safety for all users, Central Coast Council specified Moddex modular railings from the outset.

“The pathway covers 3.7 kilometres of shared footpaths, cycleways, bridges, elevated walkways and retaining walls,” says Keith Smith, Managing Director of head contractor Bolte Civil.

“For sections where there was a risk of falls and handrails were needed, Moddex products were included in the plans as a preferred option, with the drawings specifying, ‘Moddex or approved equivalent.’ We could see why, with the benefits they offer in both installation and long-term use.”

Curved to follow nature’s contours

For Bolte Civil and their installers, J&M Earthworks, the modular, pre-engineered systems provided the flexibility to design handrails that fit seamlessly with the natural environment.

“It has to work, but it also has to look good,” says Keith. “The pathway runs through protected rainforest, with lots of curves and turns to fit the landscape. We surveyed the surfaces, created CAD files, and worked closely with Moddex to make sure the design and fit were spot on before production.”

One key advantage was customising the curves to match the path’s radius.

“The curved railings follow the grades and turns perfectly, both horizontally and vertically, which looks fantastic,” Keith explains. “Moddex gave us the time we needed to get things right, and their team made sure everything fit perfectly.“

Quick, accurate installation with custom design

J&M Earthworks also benefited from Moddex’s logistical support, making installation smooth despite tricky site access.

“The system’s modular design speeds up installation because there’s no welding involved,” says owner John Gorey. “The design and installation drawings were so accurate that we could mark and drill the holes for the studs knowing everything would fit exactly as planned.”

Co-ordination with Moddex ensured deliveries were timed perfectly to avoid site storage issues. “Once the civil works were done, we had limited access and couldn’t store much product on-site,” John adds. “Moddex helped us manage deliveries, so we had what we needed when we needed it.”

Even when surveys were adjusted before production, Moddex was able to adapt. “There were times when changes to the original survey came through, and Moddex quickly updated the design before manufacturing. Everything ended up where it needed to be—and it looks great.”

Long-term benefits of modular systems

Both J&M Earthworks and Bolte Civil agree that modular, no-weld systems are a game-changer for installers, contractors and clients.

The fact Moddex can manufacture to suit site constraints is a huge advantage. And in the long run, because it’s modular, any damaged sections can be replaced without dealing with welded components. For Council, that’s a big plus in terms of maintenance.

Keith Smith, Managing Director of head contractor Bolte Civil.

Find out more

To learn more about our products and specification services, get in touch with our team of experts.